— News —

customer service +86 18020721390

customer service +86 18020721390 Email:sakyzeng@foxmail.com

Mobile:+86 18020721390

Telephone:+86 18020721390

Address:Hongshan Hotel, No. 42 Hongshanhu Road, Beijie Street, Xixiu District, Anshun City, Guizhou Province

Product information

Release time:2024-01-08 09:24:50 popularity:

1、 What does digital transformation in manufacturing mean?

In today's manufacturing industry, digital transformation means enhancing traditional manufacturing methods, products, and labor processes by integrating digital technologies. These technologies include a series of innovations, such as automation software, e-commerce systems, sensors, industrial robots, etc.

WeChat images_ 20231225120840. png

2、 The main goals of digital transformation in the manufacturing industry are as follows:

1. Improve operational efficiency, reduce operational costs, and optimize revenue generation.

2. Improve product quality.

3. Simplify customer interaction to improve the overall customer experience, especially simplifying the ordering process.

4. Enhance decision-making ability through data-driven insights.

5. Capable of quickly adapting to customer needs and market dynamics, ensuring competitive advantage in dynamic environments.

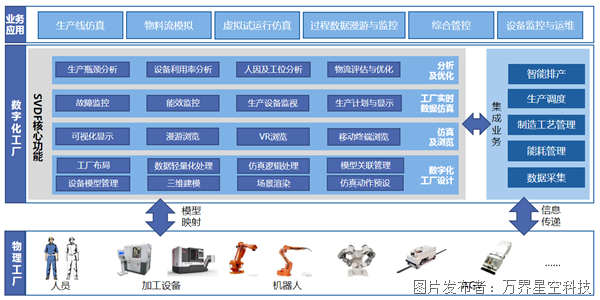

3、 Digital workshop architecture

To achieve digital production workshops, corresponding automation equipment, industrial networks, IT facilities, and software support are also needed to achieve the functions of digital workshops. The architecture of digital workshop equipment includes sensing layer, control layer, and execution layer:

1. Sensing layer:

This layer includes sensors, digital device interfaces, and input/output devices, etc., used to collect real-time data in the workshop and receive operation instructions.

2. Control layer:

The lower part includes devices such as PLC and industrial internet, which are used to gather sensor layer data and form operation instructions, and transmit data through the device communication network. The upper part includes industrial control computers, PC workstations and other equipment, as well as software systems such as HMI and SCADA, which are used to generate business data and communicate with the execution layer through the operation information network to achieve data exchange and transmission.

3. Execution layer:

This layer includes IT equipment and facilities such as servers, PCs, PDAs, as well as management software such as MES and WMS, to achieve various functions of the workshop production control layer.

WeChat images_ 20231225120904. png

The digitalization of manufacturing industry is the result of the intersection, integration, development, and application of manufacturing technology, computer technology, network technology, and management science. It is an inevitable trend for manufacturing enterprises, manufacturing systems, production processes, and production systems to continuously achieve digitalization.

To improve operational efficiency and achieve intelligent manufacturing, enterprises must attach importance to the seamless connection between their information systems and equipment automatic control systems. Wanjie Starry Sky Technology MES plays a crucial role as a bridge between the two. Focusing on the application of MES and related technologies is one of the fundamental and key tasks in promoting the construction of intelligent manufacturing.

Related recommendations